The roasting process

The new process for high performance roasting

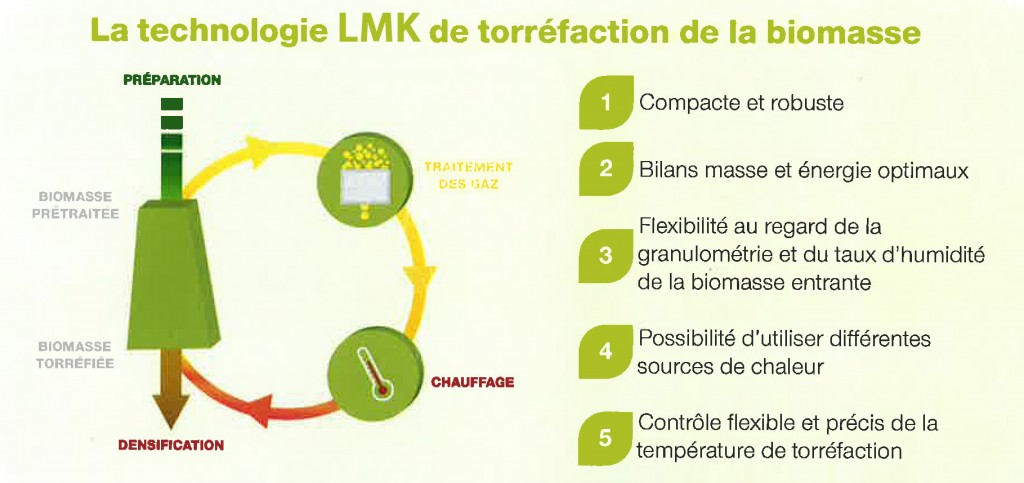

The roasting process LMK : innovative technology specifically designed to enhance , optimize and standardize biomass fuel.

Roasting prototype installed on the LMK Energy site in Mazingarbe (France).

The roasting process LMK is based on a moving technology ” directly heated. The heat treatment is carried out continuously in a column roasting, where the flow of biomass and hot gases flow vertically, against the current.

Biomass through a neutral gas stream whose temperature is gradually increased to 240°C (for wood).

After a drying phase of the biomass, increase in temperature causes the release of light volatile organic compounds. Hemicellulose polymers decompose, weakening the fibrous structure of the biomass and conferring him improved grindability.

The torrefied biomass is removed at the base of the column roasting, and then cooled.

Coal Green Features: The Bio-Coal.

Higher calorific power

20,5 - 24 gigajoules per tonne

Humidity rate

Less than 5%

The torrefied biomass, also called ” green coal” is a refined solid fuel obtained by roasting from lignocellulosic biomass such as residues from the forest or agricultural industry.

Green coal has specific characteristics that make it an excellent substitute for fossil coal for heat and electricity :

- increased energy density

- reduces humidity

- improved grindability

The properties of the torrefied biomass facilitate its transport, storage, handling, and combustion, in comparison with the raw biomass.